Solution Concept

Working together to innovate superior products

We work in synergetic partnerships

To innovate superior products, we believe in the combination of expertise. We are your partner from idea to serial production.

You

Your product and market expertise

herone

herone expertise, material, design, manufacturing

Partnership

A synergetic partnership takes place

Development

Individual product development

Production

Specific, market ready solution

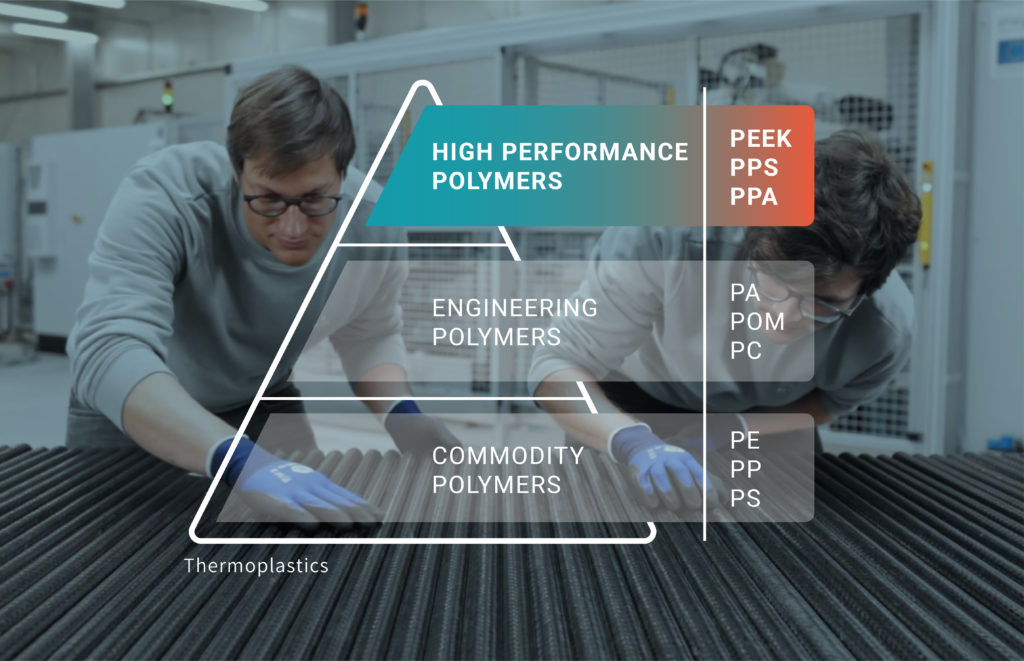

Our thermoplastic advantage

Thermoplastic Composites have superior material and processing properties – we call them the thermoplastic advantage. It is the basis of our integral design approach and the herone technology. What is the advantage for your application?

Performance advantage

- damage tolerant

- chemical resistant

- extended operating temperatures

Processing advantage

- high rate

- thermoformable

- weldable

Sustainability advantage

- 100% recyclable

- harmless handling

- energy-efficient processing

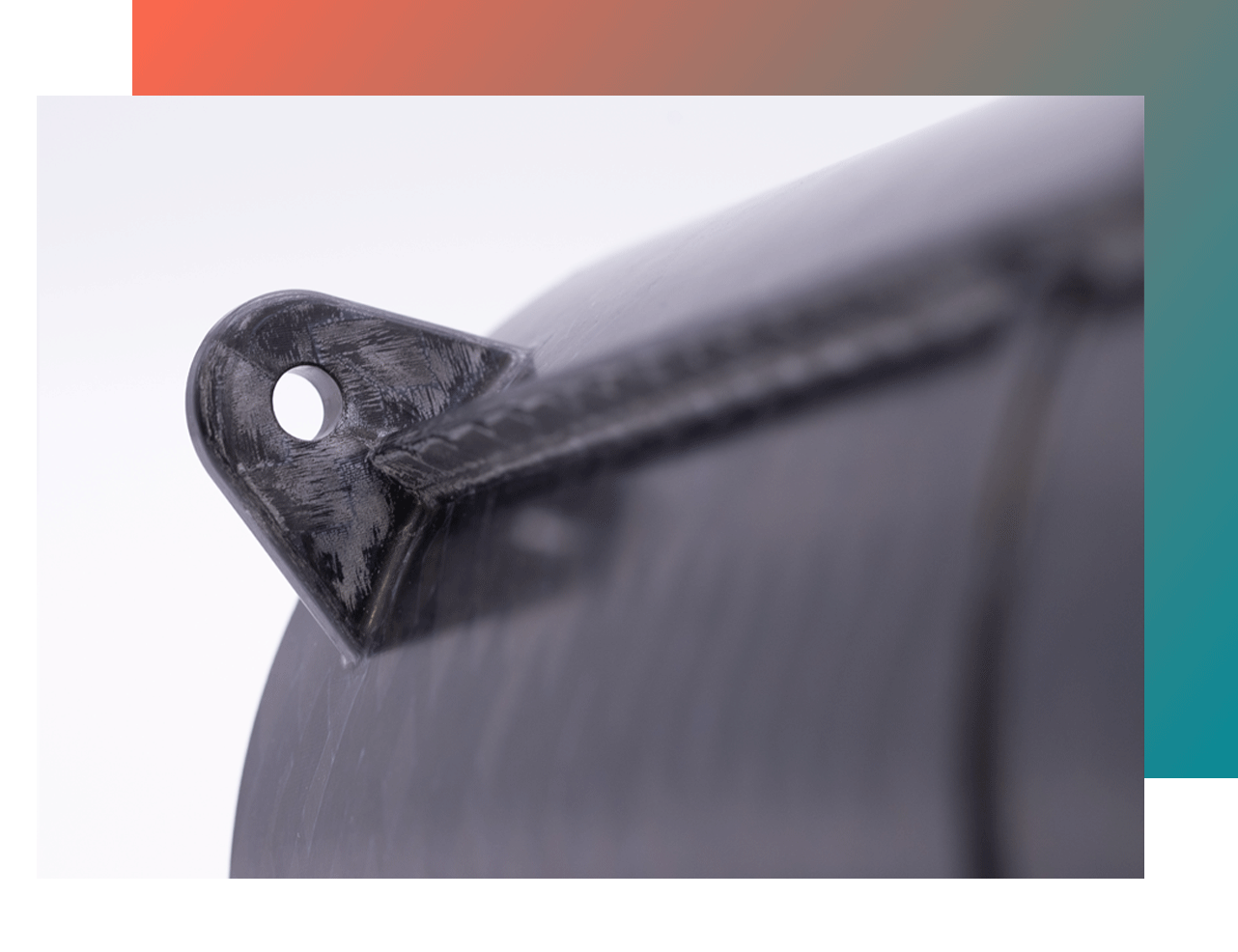

Integral Design

We simplify the part design and integrate functions out of the same thermoplastic material. That is our integral design approach to make parts ultralight, robust and cost-effective.

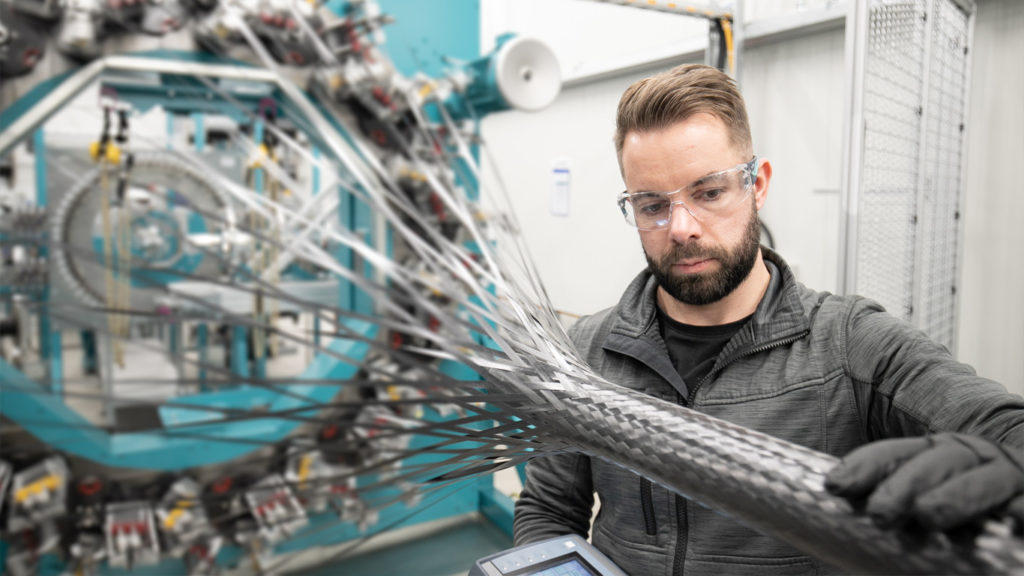

The herone Technology

We combine automated textile preforming with efficient press molding for the production of thermoplastic composite parts in minutes rather than hours.

Processing step I

Textile Preforming

Pre-consolidated thermoplastic composite tapes are braided into a near net shape multilayer tape preform. Multiple non-crimp axial-oriented layers can be integrated inline. The tape preform is automatically cut to the final part length. The full automation of the process secures high preforming rates in combination with reproduceable high-quality.

Processing step II

Press Moulding

The tape preforms and application specific functional elements are consolidated in a one-shot consolidation step. The functional elements are premanufactured from a compatible thermoplastic polymer. Their fiber architecture is adapted to the specific load situation. Using the same thermoplastic material throughout the part, results in a simplified part without fasteners or interfaces.