Products & Services

From idea to serial production

// products

Thermoplastic composite profiles

Thermoplastic composite profiles

with integral functionality

We develop and produce cost-effective ultralight

composite profiles with tailored performance and integral

functionality to go beyond limits

Ultralight

We use the thermoplastic advantage and strive for a simplified part design to provide you the lightweight potential you need.

Functional

We use our design expertise and the TP-advantage to tailor the part functionality to your individual needs.

Sustainable

Our lightweight products enable you to save resources and we actively strive towards a circular economy, making them from recycled and recyclable material.

Cost-effective

We simplify composite parts and use our platform technology to integrate functionality, automate manufacturing and provide you the most cost-effective solution.

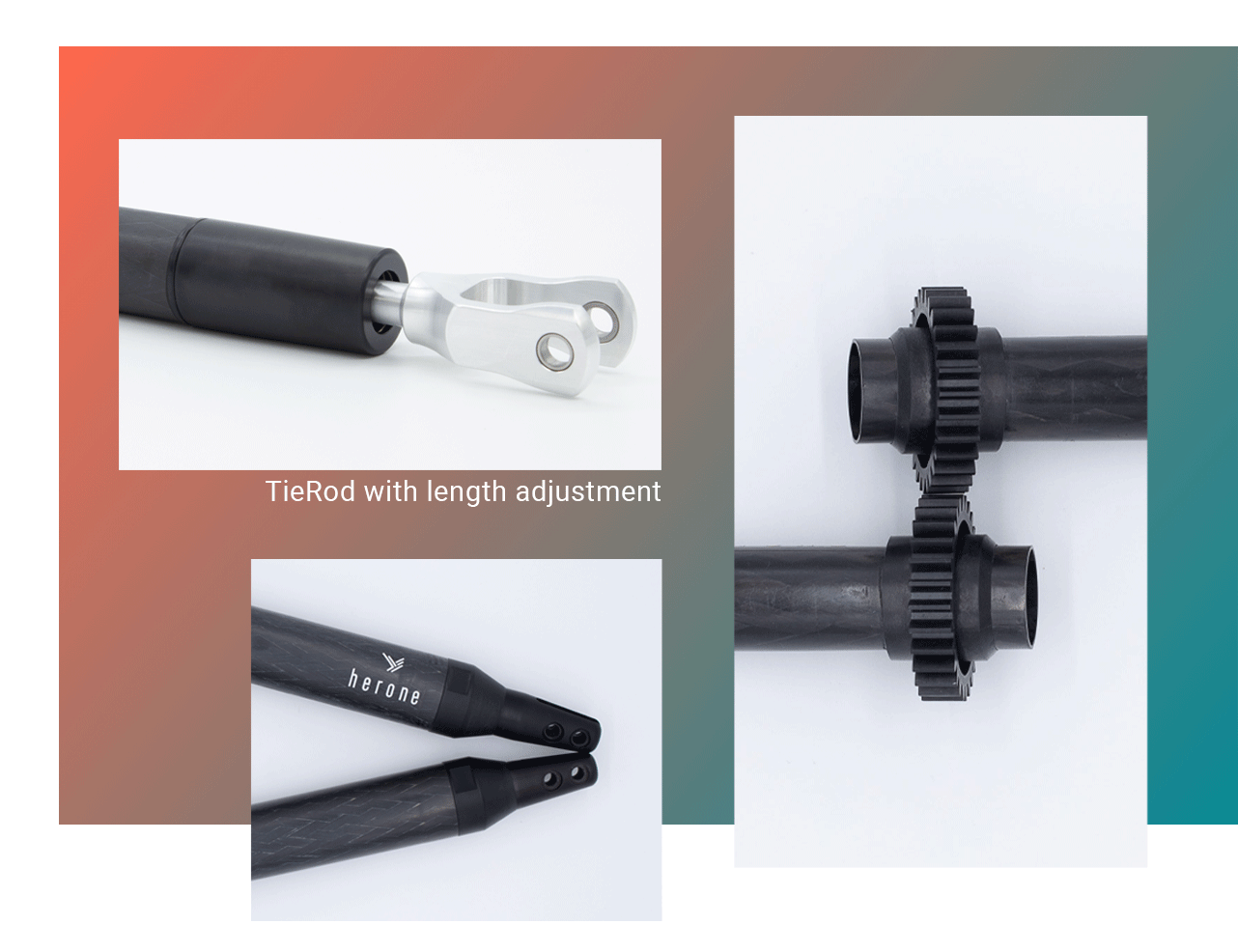

Motion & Load Transfer

Thermoplastics composites (TPCs) have outstanding specific mechanical properties that make them eminently suitable to transfer loads in parts with a clear load path like struts and driveshafts. The meltability of TPCs allows to integrate load transfer elements directly into the part to make them lighter, more robust and cost-effective.

- Struts & Rods

- Drive shafts

- Shafts with levers

- Truss elements

Fluid Transport & Storage

The chemical resistance of TPCs in combination with their thermo-mechanical properties offer superior performance in harsh and challenging environments. Using non-metallic fittings and integrating them directly into the part enables lighter, more resistant and corrosion free solutions.

- Fuel pipes

- Hydraulic pipes

- Electrical resistance pipes

- LH2/LOX pipes

- H2 tanks

- Air ducts

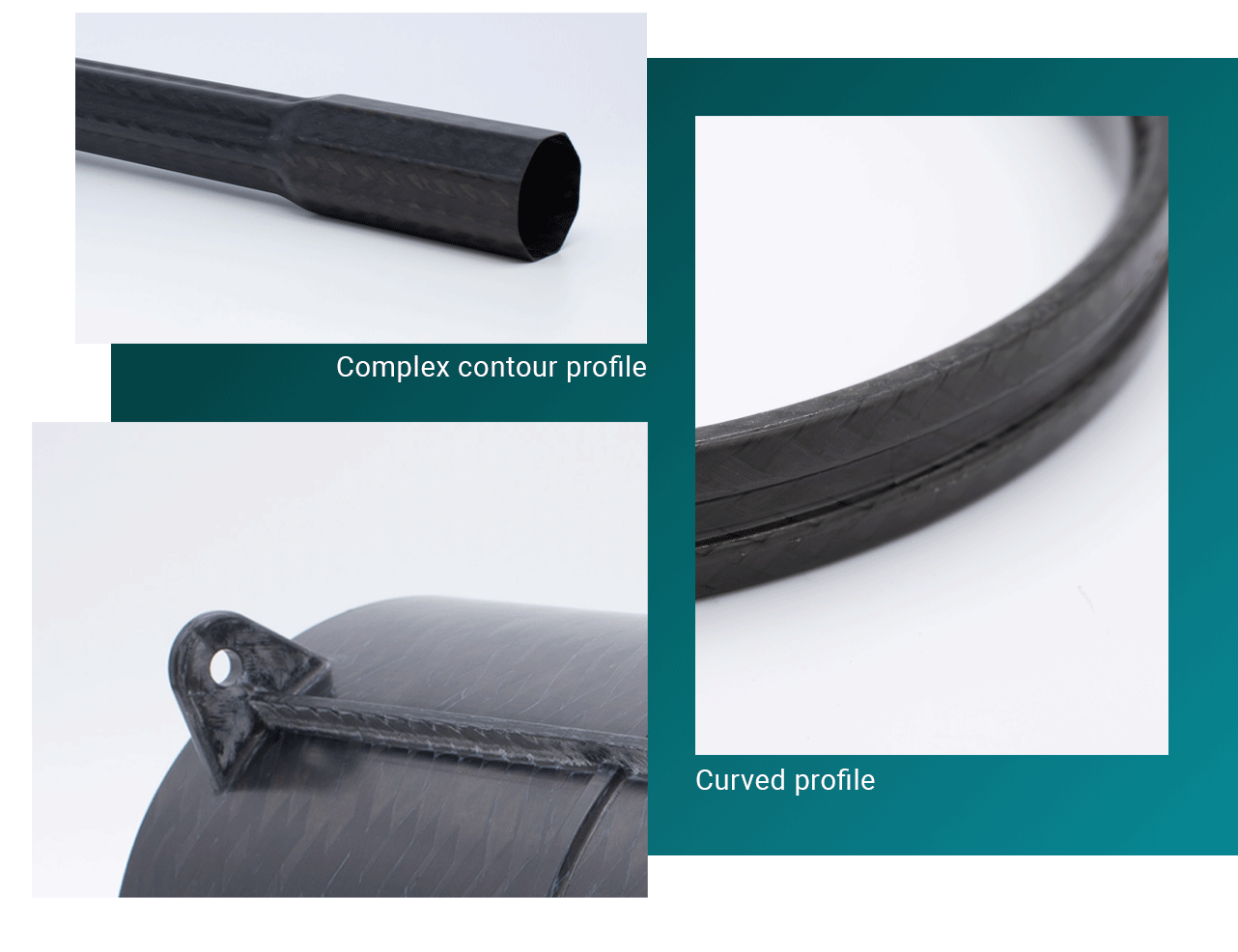

Complex Shape & Functionality

TPCs can be welded and thermoformed. The herone technology allows curvature, branches, and variation of cross-section. We use that to increase the design space and add additional value.

- Fan casings

- Blades

- Frame segments

- Handlebars

- Rackets

- Seat frames

- Winglet center spars

// our service

Idea to serial production

We offer you a synergetic partnership form the definition of requirements through product development to the serial production.

Product, costs and life cycle analysis

Analyze the product & the requirements, business case analysis determine the environmental impact

Testing & validation

Characterize material / test prototypes / quality & product performance validation / qualification

Design & prototyping

Design & engineering / proof of concept / prototyping

Production

First article inspection / serial part production